Using Pre-Shipment Inspections to Ensure Product Quality and Satisfaction

QC photos are your critical window into product reality before shipment.

Key Areas to Inspect with Precision

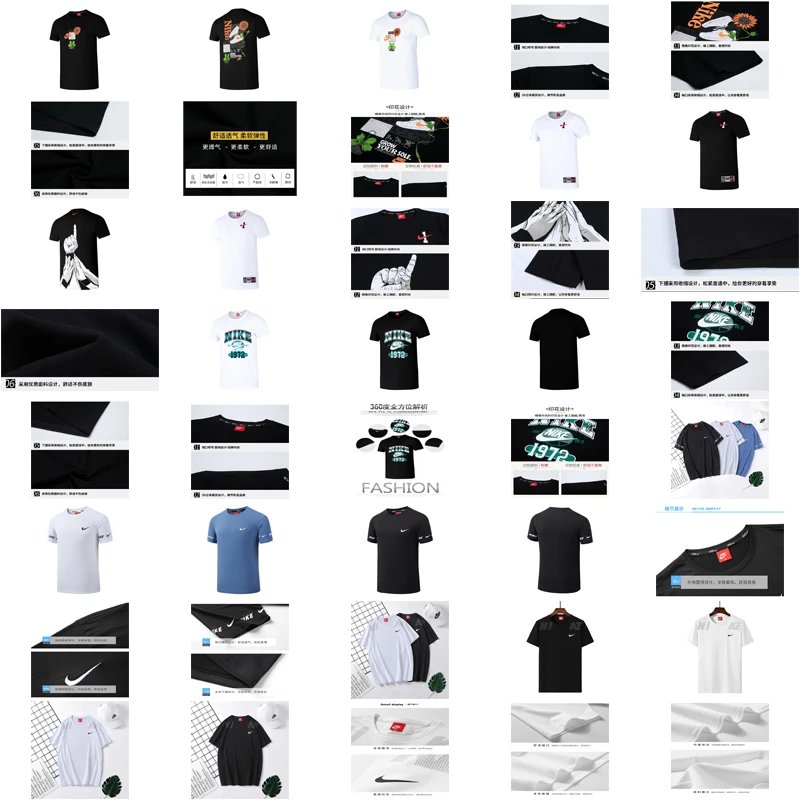

1. Stitching & Construction

Zoom in on seams and joints. Look for consistent, straight stitching with no loose threads, skipped stitches, or uneven spacing. Check stress points for reinforced stitching.

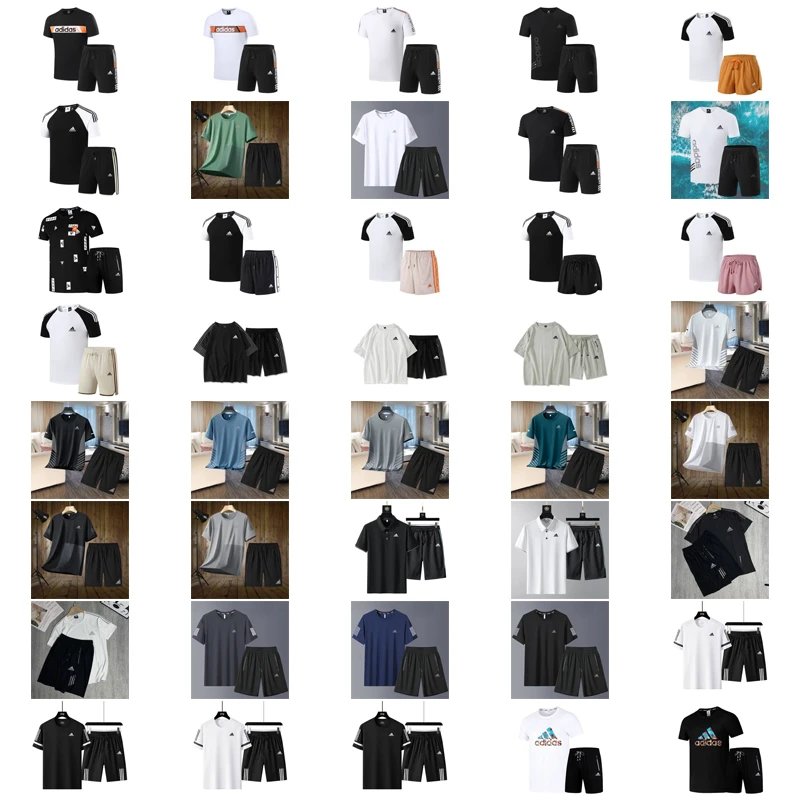

2. Color Accuracy & Material

Compare the photo colors to your Pantone or approved swatch. Assess material drape, texture, and consistency across all parts. Watch for stains, discolorations, or material flaws.

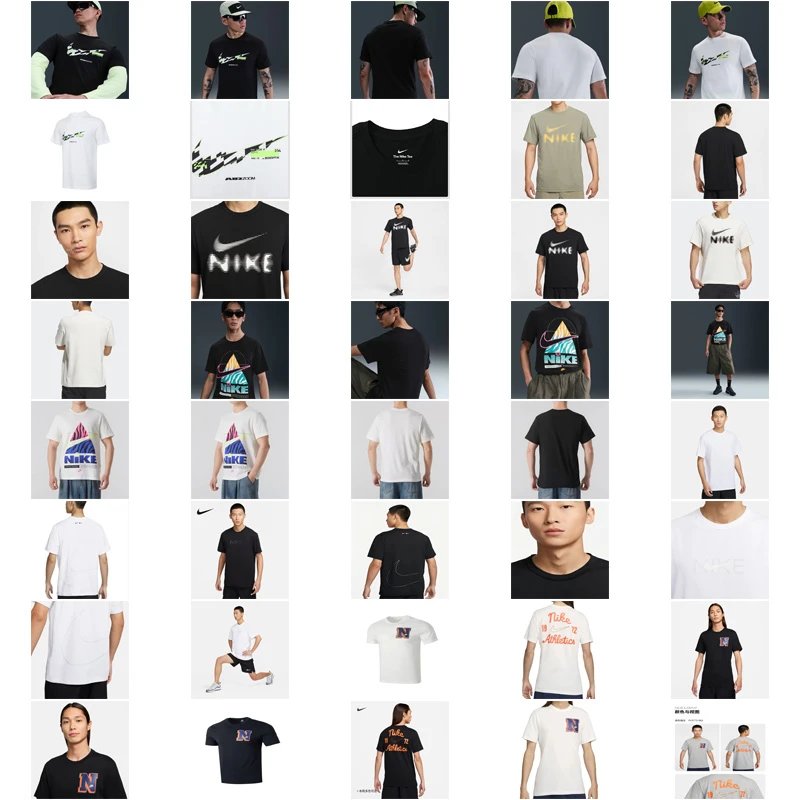

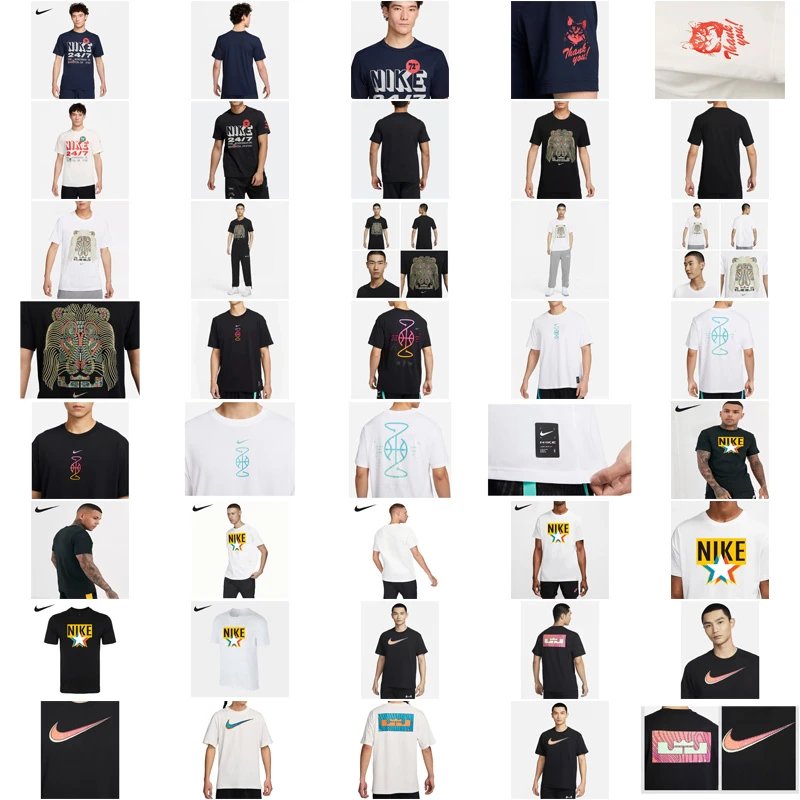

3. Logo & Label Placement

Verify exact positioning, alignment, symmetry, and clarity of printed or embroidered logos. Check care labels for correct information and secure attachment.

4. Overall Workmanship & Finishing

Examine overall symmetry, proper alignment of parts (e.g., pockets, sleeves), and neatness of finishing touches like buttons, zippers, and hardware.

Mastering the CNFANS QC Photo Viewer

- Zoom & Pan:

- Multiple Angles:

- Comparison Method:

- Lighting Assessment:

- Annotation & Feedback:

- Multiple Angles:

Effective Approval Workflow

- Systematic Review:

- Document Questions:

- Communicate Clearly:

- Final Verification:

- Document Questions: